Turning Vision into Reality: Our Projects

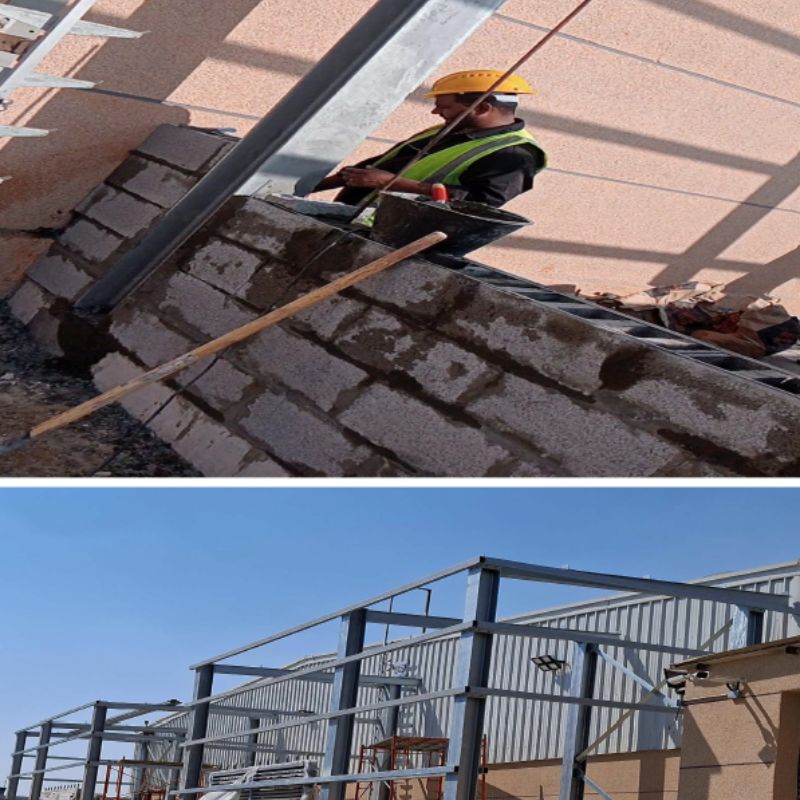

Oil Chemistry Dammam

We had the privilege of executing a specialized project for Oil Chemistry, a respected industrial client based in Dammam, Kingdom of Saudi Arabia. The project involved the complete fabrication, supply, and erection of a steel structure designated for an Air Compressor Room within their operational facility.

Our scope of work began with the engineering design and detailing of the steel structure, tailored to meet the specific requirements of the compressor system and the client’s site conditions. Following the approval of design drawings, our fabrication team carried out precise cutting, welding, and assembly using high-quality steel materials, ensuring structural strength, safety, and durability.

Once fabrication was completed at our workshop, the components were securely transported to the site. Our erection team then proceeded with the on-site installation, adhering to strict safety protocols and project timelines. The structure was successfully erected with precision alignment, anchoring, and finishing as per industry standards.

This project not only highlights our capabilities in delivering custom-built steel structures but also reflects our commitment to quality, timely delivery, and client satisfaction. The successful completion of this project for Oil Chemistry adds to our growing portfolio of industrial infrastructure solutions across the Gulf region.

Midad Chemicals Project

We successfully executed two specialized supply projects for Midad Chemicals Company, delivering high-quality industrial components tailored to their operational needs.

The scope of the first project involved the comprehensive supply of industrial-grade pipes, fittings, and valves, including all associated specifications, items, and contractual terms. Our team ensured that every component met the client’s stringent quality standards and was delivered on time to support their ongoing plant operations.

The second project focused on the supply of precision-engineered valves manufactured from SS316L stainless steel, known for its superior corrosion resistance and performance in chemical processing environments. These valves were selected to meet the specific requirements of Midad Chemicals’ advanced production systems, enhancing durability and operational efficiency.

These projects reflect our commitment to delivering top-tier fabrication and supply solutions for the chemical and industrial sectors. The accompanying images provide a closer look at the materials and components delivered during the execution phase.

Siraj Power Project

We partnered with Siraj Power, a leading clean energy solutions provider under Positive Zero, to deliver high-quality steel fabrication and supply services for multiple solar-integrated carport structures. These structures were critical components in their sustainable energy initiatives, designed to support solar module installations across designated parking areas.

A-5 Carport Steel Structure: Engineered and delivered with precision to serve as a durable base for solar panel installations.

B-5 Down Carpark Structure: Customized to meet specific load and space requirements for lower-level parking.

B-5 Double Cantilever Structure: Designed for extended coverage and optimal structural balance.

These installations exemplify our expertise in supporting renewable energy infrastructure through expert steel fabrication and dependable industrial mechanical services. Our contribution to Siraj Power’s project reinforces our role in advancing green energy solutions across the region.

Premium Atlas Project

- Installed two new blenders to increase mixing capacity

- Installed a 50,000L 4-tank system for optimized storage and processing

- Completed blender outlet connections for seamless integration

- Executed trench extension to support new utility lines

- Performed all associated electrical work ensuring safe and efficient operations

Almoayyed

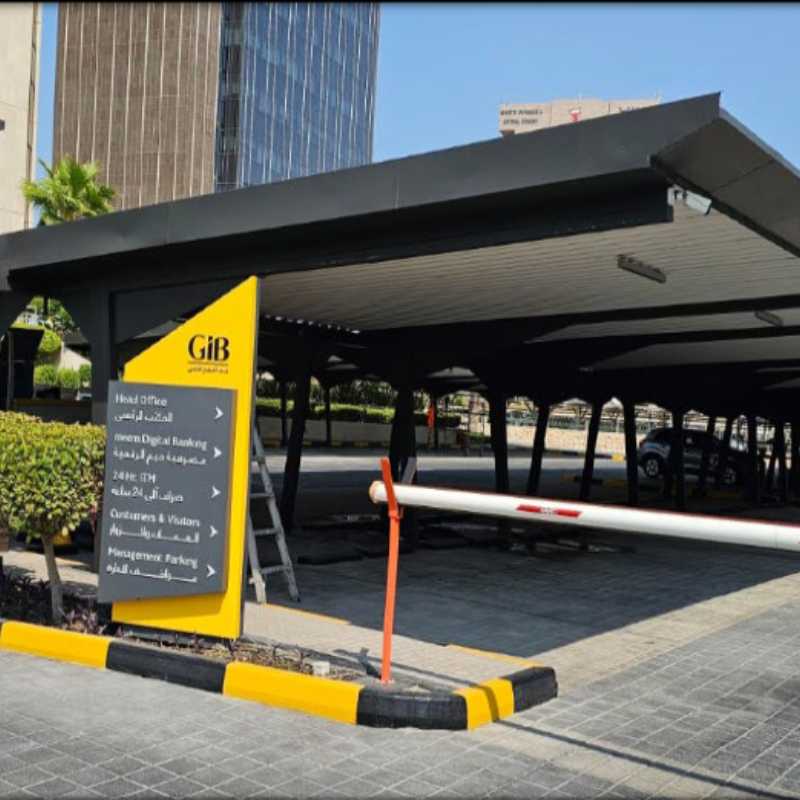

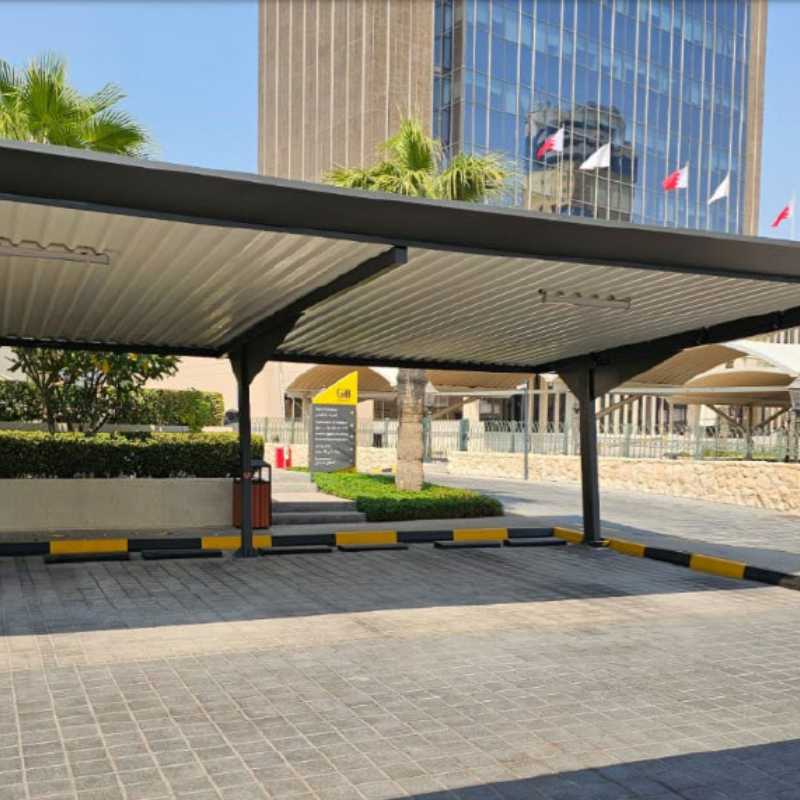

GIB Bank Manama Bahrain

As part of Almoayyed International’s commitment to renewable energy, we were entrusted with the fabrication and installation of a complete solar PV mounting system tailored for a commercial-scale deployment.

Our team engineered and fabricated custom steel mounting structures designed to support photovoltaic modules under local environmental and structural conditions. Precision and quality were key throughout the fabrication phase to ensure durability, corrosion resistance, and long-term performance.

Following fabrication, we completed the on-site installation of solar modules, ensuring proper alignment, secure fastening, and efficient integration with the overall solar energy system. All work was executed in close coordination with the client’s technical team, adhering to strict quality and safety standards.

This project underscores our capability to support clean energy infrastructure with end-to-end fabrication and installation solutions, contributing to Bahrain’s growing solar energy sector.

Everest Fabrication and Supply Project

We successfully executed the fabrication and supply of customized industrial components for Everest Electrical Building Materials WLL, supporting their operational infrastructure with reliable and durable solutions.

The scope of work included the fabrication and supply of step ladders, designed for safe and efficient access within their facility. These ladders were manufactured to meet industrial safety standards and tailored to the client’s specifications.

In addition, we provided additional structural support components, ensuring enhanced stability and functionality across key operational areas.

This project reflects our ongoing commitment to delivering precision-engineered solutions that support workplace safety and operational efficiency.

Have a Project in Mind?

Let’s build something exceptional together. We’re ready when you are.

Request a QuoteHow does it work?

Schedule a Meeting

We begin by understanding your requirements through a quick meeting—online or in person.

Site Visit & Assessment

Our technical team visits the site to assess project needs, gather measurements, and evaluate conditions.

Our Expert

Experts Team

Receive a Price Quote

We provide a detailed quotation based on the site visit, materials, scope, and timeline.

Project Execution & Handover

Once approved, we execute the project with precision and deliver it within the agreed timeline.

What our clients Says About Us

“Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.!”

Lorem Ipsum

“Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.!”

Lorem Ipsum

“Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.!”

Lorum Ipsum

Contact Us

Ready to Elevate Your

Next Project with Us?